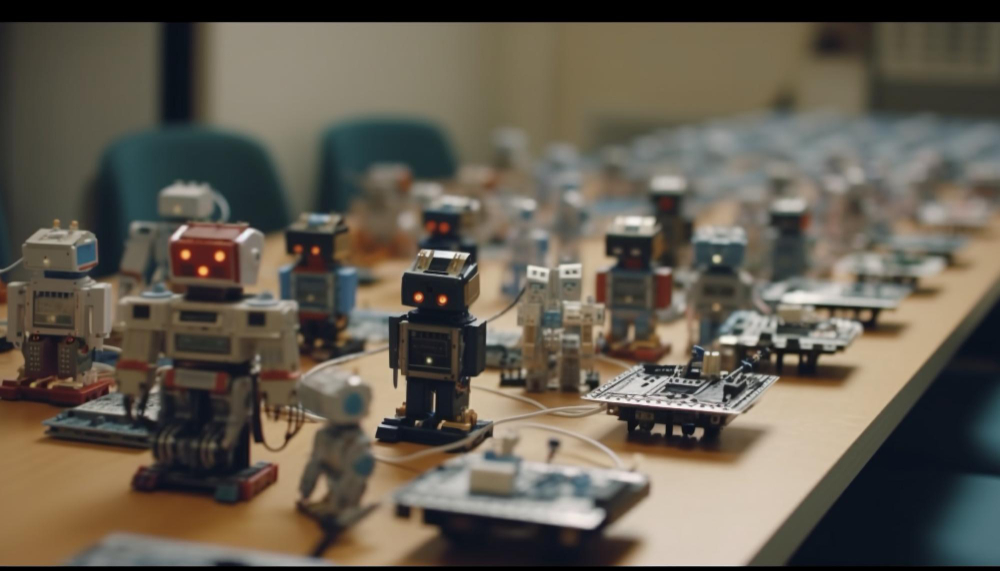

The equipment industry is experiencing a dramatic transformation, driven with the aid of the relentless march of technological innovation, incredibly the rise of robotics. This is no longer a futuristic delusion, however a tangible reality reshaping companies across the globe. From production flora to development web sites, robots are taking up tasks as soon as considered solely human, imparting potency, precision, and a level of productiveness previously unimaginable.

This article delves deep into the affect of robotics on the machinery business, exploring its multifaceted benefits, the demanding situations it items, and the long term possibilities it unlocks. We will take a look at how robots are replacing the panorama of producing, construction, and agriculture, highlighting the important thing tendencies and traits shaping this exciting new technology.

The Robot Revolution: A Force for Change in the Machinery Industry

The integration of robotics into the machinery industry isn’t always merely a technological advancement; it represents a fundamental shift in how paintings is achieved. Here’s how robotics is reshaping the landscape:

1. Increased Efficiency and Productivity: Robots are tireless laborers, working consistently with out breaks or fatigue. They can perform repetitive initiatives with unprecedented precision and velocity, drastically growing creation extent and efficiency. This translates into higher output, decrease prices, and shorter lead instances, giving businesses a aggressive edge in these days’s rapid-paced marketplace.

2. Improved Quality and Consistency: Robots are programmed for accuracy, putting off human errors which could end in inconsistencies in product quality. This meticulousness results in a far better popular of output, chopping waste and remodel, and ultimately improving client satisfaction.

three. Enhanced Safety and Worker Wellbeing: Robots can take care of risky and bodily disturbing initiatives, freeing human employees from dangerous environments and repetitive pressure injuries. This complements protection, reduces place of job accidents, and permits employees to consciousness on more professional and rewarding roles.

4. Flexibility and Adaptability: Modern robots are especially adaptable, able to being reprogrammed for special tasks and incorporated seamlessly into latest workflows. They can be customized to meet particular creation necessities, allowing companies to reply hastily to changing marketplace needs and production needs.

five. Data-Driven Optimization: Robotics is carefully connected to data series and analysis. Robots can tune their performance, become aware of bottlenecks, and provide precious insights that could be used to optimize workflows and enhance potency. This info-driven strategy permits businesses to make knowledgeable selections and always raise their operations.

Case Studies: Real-World Examples of Robotic Transformation

The impact of robotics is no longer theoretical; it’s miles being found out in sensible applications across diverse sectors of the machinery industry:

a) Manufacturing:

- Automotive Industry: Robots are vital to automobile production, performing tasks like welding, portray, assembly, and quality control. They have revolutionized the industry, enabling the mass production of high-quality vehicles at competitive prices.

- Electronics Manufacturing: Robots are necessary for assembling electronic factors, relatively in industries like smartphones and computer systems, the place precision and speed are paramount. They have enabled the miniaturization and complexity of contemporary electronics.

- Pharmaceuticals: Robots are hired in drug manufacturing, packaging, and caliber management, guaranteeing sterility, accuracy, and compliance with stringent guidelines. Their automation is critical for the safe and efficient production of lifestyles-saving medicines.

b) Construction:

- Heavy Lifting and Material Handling: Robots are a growing number of used for tasks like lifting heavy materials, transporting components, and getting ready development sites, making construction initiatives faster, more secure, and extra effective.

- Automated Masonry and Concrete Pouring: Robots can now lay bricks, pour concrete, or even bring together prefabricated systems, cutting labor prices and improving construction caliber.

- Inspection and Maintenance: Robots equipped with sensors can investigate bridges, tunnels, and other infrastructure for harm, guaranteeing safety and preventing costly repairs.

c) Agriculture:

- Precision Farming: Robots can autonomously navigate fields, planting seeds, applying fertilizers, and harvesting vegetation with unparalleled precision. This optimizes resource use, minimizes waste, and maximizes yields.

- Automated Livestock Management: Robots are used to monitor cattle fitness, feed animals, and manipulate dairy operations, improving productivity and animal welfare.

- Data Collection and Analysis: Robots collect valuable data on soil conditions, crop health, and livestock conduct, providing farmers with crucial insights to optimize production practices.

The Challenges and Considerations of Robotic Implementation

While the benefits of robotics are simple, implementing those technologies also gifts challenges:

1. Cost of Implementation: Investing in robotic approaches may be highly-priced, requiring enormous capital investment and potentially excessive maintenance costs. Careful making plans and feasibility evaluation are important before adopting robotics.

2. Technical Expertise: Operating and preserving robotic techniques calls for specialized technical expertise, which can also necessitate coaching present workforce or hiring skilled specialists.

3. Job Displacement Concerns: Automation can lead to process displacement as robots replace human workers in sure roles. It’s indispensable to cope with these worries thru upskilling programs, retraining initiatives, and creating new alternatives in regions the place human abilties are still particularly valued.

four. Ethical Considerations: As robotics becomes more sophisticated, ethical questions stand up regarding their impact on society, privateness, and the future of work. Open dialogue and responsible improvement are vital to make certain that robotics is used ethically and for the betterment of humanity.

The Future of Robotics in the Machinery Industry

The future of robotics in the machinery industry is brimming with possibilities. Here are some key trends to look at:

1. Artificial Intelligence and Machine Learning: AI and device getting to know will empower robots to research and adapt independently, bettering their decision-making abilities and permitting them to tackle more and more complicated tasks.

2. Collaborative Robots (Cobots): Cobots are designed to work appropriately along human beings, presenting assistance and augmenting human talents. This collaborative strategy will create more flexible and effective work environments.

3. Internet of Things (IoT): Connecting robots to the net will enable actual-time data sharing, far off tracking, and predictive maintenance, optimizing efficiency and slicing downtime.

4. 3D Printing and Additive Manufacturing: Robots geared up with 3D printing potential will revolutionize manufacturing, allowing for on-call for production of custom components and aspects, in addition enhancing flexibility and efficiency.

5. Robotics in Service Industries: The software of robotics is increasing beyond manufacturing and construction, with robots being deployed in service industries like healthcare, logistics, and hospitality, automating tasks and improving service shipping.

Conclusion: Embracing the Robotic Revolution

The rise of robotics is an inevitable pressure reshaping the machinery industry. It gives unparalleled alternatives for increased efficiency, productivity, and innovation, whilst offering challenges that want to be addressed thoughtfully and proactively. Embracing this technological revolution requires businesses to evolve, spend money on coaching, and prioritize moral issues. By doing so, they can harness the electricity of robots to liberate a way forward for exceptional growth, productivity, and prosperity.